What are the process characteristics of the diffusion furnace?

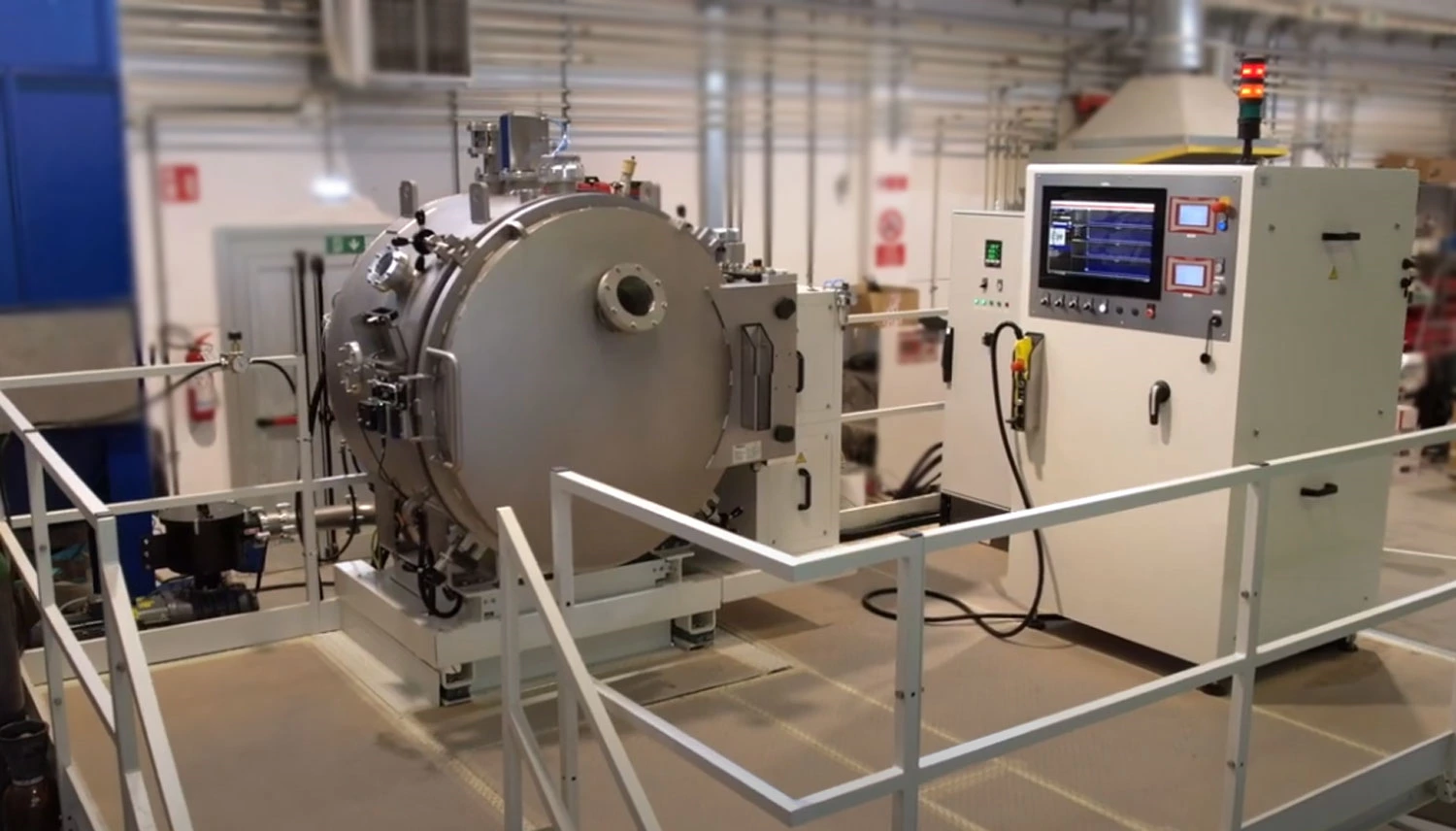

The diffusion furnace is a key process apparatus used in the development and manufacturing of semiconductor devices, including transistors, SCRs, and integrated circuits. It is primarily employed for diffusion and oxidation procedures. The main components of the diffusion furnace consist of the control system, purification section, resistance heating chamber, and gas delivery system.

The control section primarily manages the inlet and outlet operations, while the resistance heating furnace regulates the temperature within the diffusion furnace. The gas delivery system controls the flow rate of the diffusion source and manages exhaust emissions. To operate the diffusion furnace process control software, press the "Power on" button to start the computer, then double-click the "Diffusion Monitoring System" icon to launch the software.

Enter your username and password to sign in.

The temperature control of the diffusion furnace is represented by three analog temperature controller displays on the interface, each corresponding to a specific segment of the furnace’s three-stage temperature controller. The diffusion furnace is a type of resistance furnace with automatic temperature regulation, composed of a temperature controller, SCR device, and furnace body. The furnace body includes insulation material, heating wires, and a furnace tube. The temperature controller maintains a stable and uniform furnace temperature by managing the heating elements, ensuring compliance with process requirements.