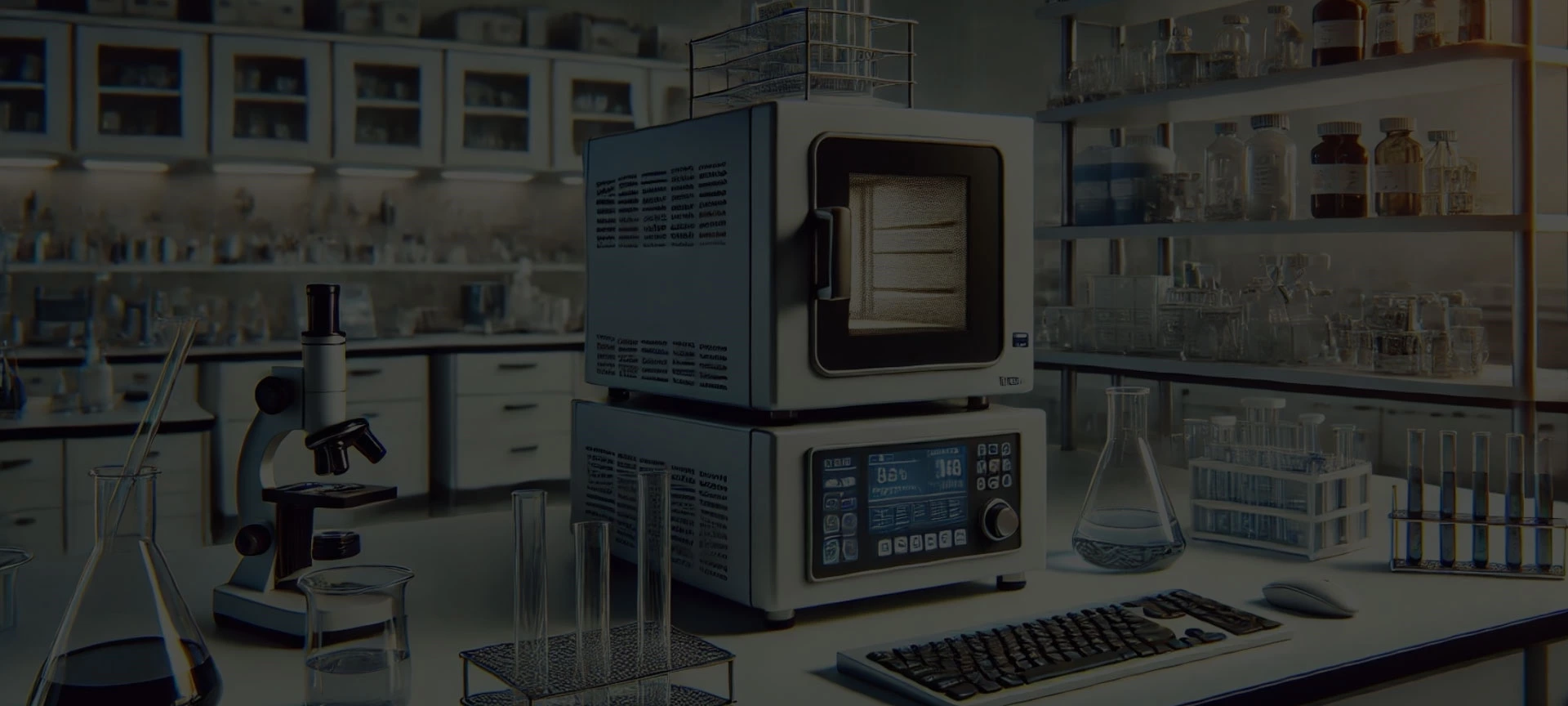

Atmosphere furnaces are widely utilized in industrial and laboratory research for heat treatment under inert atmospheres. These furnaces come equipped with a vacuum pump, gas flow meter, and needle valves to control vacuum and gas purging. Typically, argon (Ar) and nitrogen (N2) gases are employed to establish the inert environment. For applications requiring hydrogen gas, we also manufacture atmosphere furnaces with explosion-proof safety features.

In an atmosphere furnace, a slight vacuum (up to 0.1 MPa) is generated using a rotary vane oil-filled vacuum pump, followed by purging with inert gases such as argon or nitrogen. This method surrounds the material—commonly metals and ceramics—with argon or nitrogen gas to prevent oxidation. These inert atmosphere furnaces are employed for processes like annealing, brazing, and heat treatment of oxidation-sensitive materials.

Facerom is a prominent atmosphere furnace manufacturer in India, producing furnaces with various operating temperature ranges (1100°C, 1300°C, and 1600°C) and heating zone sizes. Each inert gas furnace includes a rotary vane vacuum pump and is equipped with gas inlet and outlet valves, a gas flow meter, and a dial-type pressure gauge. For pricing information, please send your inquiry via email, and we will provide a budgetary quote along with details about installation.

Atmosphere furnaces Features & Benefits

- Complete regulation of an inert gas environment maintained under vacuum conditions.

- Available in 1200°C, 1400°C and 1700°C temperature

- Superior door sealing technology ensures no inert gas escapes.

- Door safety limit switch prevents heater operation when the door is open.

- Temperature controller with programmable ramp and soak functions for precise thermal regulation.

- Fibrous alumina insulation of superior purity.

- Vacuum pump filled with oil, equipped with a silicone rubber hose.

- Optional inclusion of a gas mixing channel.

- Steel structure with double walls and integrated fan cooling system.