Best 5 Furnaces for Laboratory

A laboratory furnace plays an essential role in any lab environment by carrying out various important tasks. Essentially, these furnaces operate through convection and are widely utilized in both manufacturing and scientific research.

When choosing a furnace, experts primarily focus on the required operating temperature. Additionally, they consider the appropriate furnace design and configuration, with options like tubular or chamber furnaces available.

Continue reading to gain a deeper understanding of laboratory furnaces.

Operation of A Laboratory Furnace

Like other furnaces, a laboratory furnace heats a sample inside its chamber using a heat source. The furnace is heated through convective heat transfer, which occurs via either mechanical or natural (gravitational) convection.

In mechanical convection, laboratory furnaces employ baffles and blowers within the chamber. This setup accelerates heating and ensures a more uniform temperature distribution throughout the furnace.

In gravitational convection, warmer air rises and pushes cooler air toward the heating element, gradually raising the entire chamber to the target temperature. This approach is characterized by uneven heat distribution, higher energy consumption, and longer preheating periods.

Considering the convection methods discussed earlier, it is clear why mechanical convection is preferred by experts. Additionally, key functions of laboratory furnaces include baking—heating the sample without removing moisture, drying—eliminating moisture from the sample, and curing—inducing physical or chemical changes in the sample.

5 Types of Laboratory Furnaces

Laboratory furnaces provide consistent heating for samples and materials in laboratory environments. They are typically constructed from high-temperature refractory materials to withstand extreme heat without deterioration.

Laboratory furnaces frequently operate continuously for long durations, sometimes lasting several months to complete a processing cycle. This article reviews five types of laboratory furnaces, highlighting their advantages and applications.

Box Laboratory Furnaces

Box furnaces feature swing-out doors or vertical lifts, enabling the placement of variously sized products inside. These laboratory furnaces are commonly used for heat-treating, calcining, pre-heating, tempering, and other high-temperature applications.

Ashing Laboratory Furnaces

Ashing laboratory furnaces are employed to determine weight changes in samples by burning off one or more components. This process removes organic material from the sample through complete combustion prior to analysis.

Ashing laboratory furnaces are frequently utilized in the food science sector to measure the mineral content of food samples. Additionally, they serve the petroleum industry by testing products to verify complete combustibility.

Top Loading Laboratory Furnaces

Top-loading furnaces are loaded from the top, with smaller items placed manually and larger ones handled using an overhead crane. Properly positioned heating elements ensure consistent temperature distribution. These furnaces are particularly suitable for glass tempering processes.

Bottom Load Laboratory Furnaces

Bottom-load furnaces are intended for handling large, heavy, or high-volume samples. They are ideal for production settings since loading from the bottom allows heating these samples without requiring cranes.

In this laboratory furnace design, the load is positioned inside the chamber and raised with an elevator hearth, ensuring even heating throughout the chamber.

Tube Laboratory Furnaces

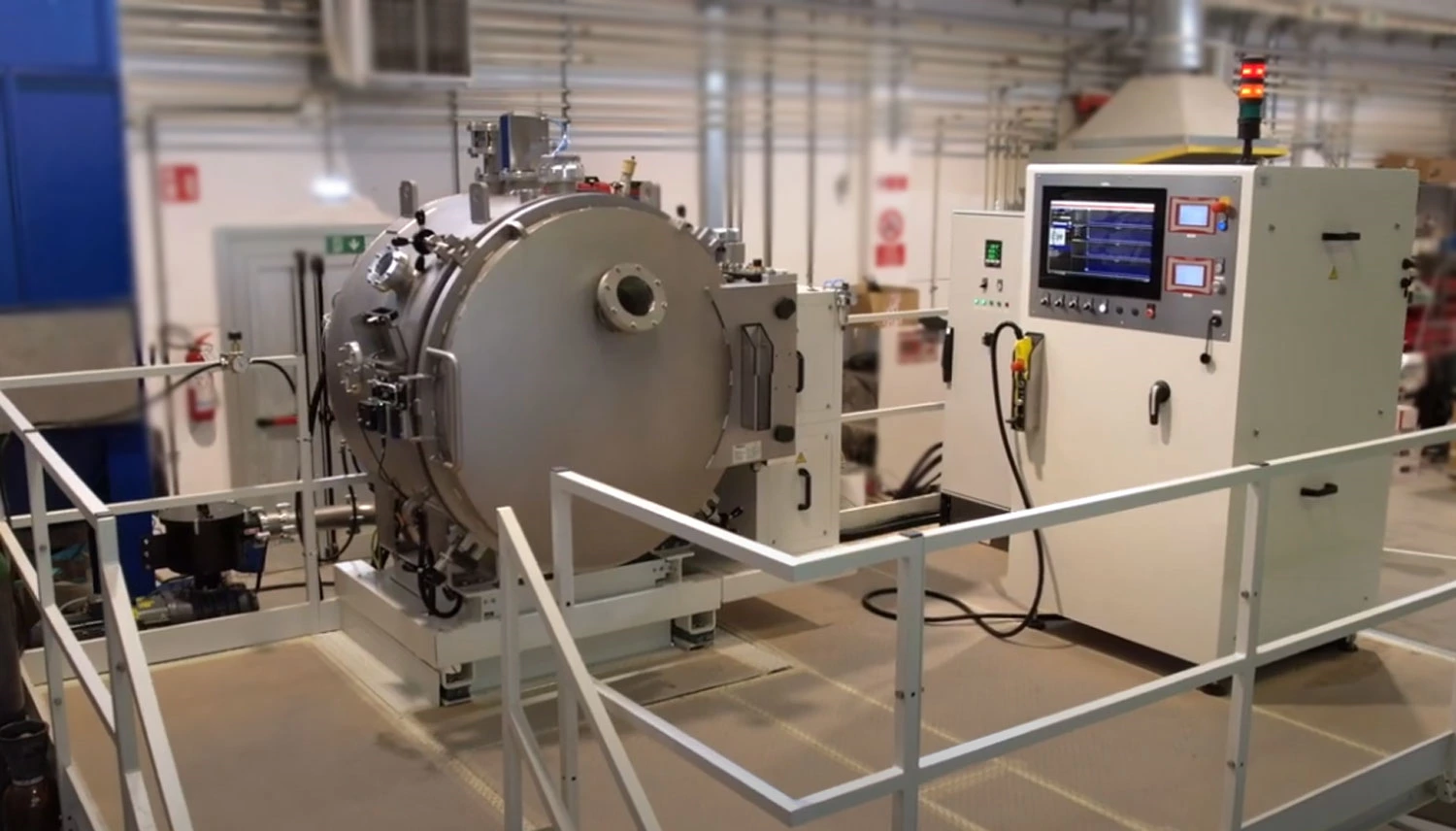

Tube furnaces are cylindrical heating devices constructed from high-temperature ceramic materials. They may consist of either two semi-cylindrical parts or a single fully cylindrical element. These furnaces provide exceptional temperature uniformity, ideal for processing both organic and inorganic substances.

Tube laboratory furnaces are utilized for various processes including organic and inorganic purification, annealing, drying, coating, accelerated aging, and additional applications.

How To Choose The Right Laboratory Furnace For You?

Laboratory furnaces play a vital role in labs and industrial processes, including drying, heating, cleaning, and thermal treatments. Various types of furnaces exist to suit different applications. When selecting a laboratory furnace, it is essential to understand its specifications and ensure key parameters—such as volume (liters), temperature range (degrees Celsius), intended use, and operation method—match the requirements of your process.

Selecting an appropriate furnace capable of reaching temperatures up to 3000 degrees Celsius

Furnace Temperature

The furnace selection is determined by the necessary operating temperature.

If your process requires a temperature of 1100 degrees Celsius, select a furnace with a maximum capacity of at least 1200 degrees Celsius.

For operations at 1400 degrees Celsius, select a furnace rated to reach up to 1500 degrees Celsius.

When operating at 1600 degrees Celsius, select a furnace capable of reaching 1700 degrees Celsius.

The furnace can operate at its maximum temperature for brief intervals; however, prolonged use at this level will reduce the lifespan of the heating elements.

Heating Elements For Furnaces

Furnaces vary in their heating elements, thermal insulation, and the methods used to secure the insulation.

Furnaces rated up to 1200 degrees Celsius feature spiral heating elements that are either threaded or embedded within thermal insulation. These elements are threaded from both the right and left sides.

Furnaces designed for temperatures up to 1600 degrees Celsius use heating elements made from silicon carbide rods, which are threaded horizontally from one end to the other.

Furnaces designed for temperatures up to 1800 degrees Celsius incorporate molybdenum disilicide heating elements, which are vertically threaded near the chamber’s ceiling along the sides.

Concealed or visible heating elements (ASHING Furnaces)

Certain ash testing processes involve materials like organic compounds, plastics, and sludge that can damage heating elements. In such cases, it is crucial to select a furnace with protected heating elements to ensure durability.

Work in an atmosphere of gases

An inert atmosphere retreat option is available, featuring a retort constructed from inconel that enables work under a continuous inert gas flow.

The return is equipped with a connection for a thermocouple sensor insertion, allowing monitoring of the components inside. When operating with hydrogen, an additional explosion protection system is necessary.

Laboratory Furnaces from Facerom

As detailed in this article, numerous types of laboratory furnaces exist, each with its own advantages and disadvantages. At Facerom, we specialize in helping you choose the ideal furnace for your needs. We offer all the furnace types described and provide expert guidance to assist you in making an informed purchase.

At Facerom, we tailor furnaces to meet your specific needs. We specialize in designing custom laboratory furnaces that align with your unique application requirements. Throughout the design, manufacturing, and post-production stages, we collaborate closely with you to ensure the final product perfectly suits your demands.